Highest product safety through valid cleaning processes

The top priority in the manufacture of food and pharmaceutical products is the safety and protection of the consumer. High-quality and safe products can only be produced with systems that can be reliably cleaned and sterilized.

We have the right solutions for this.

General

The cleaning of surfaces is important in every branch of industry. Sometimes it is a question of hygiene requirements, sometimes of safe consumption for the end consumer, sometimes of residual dirt requirements in industrial component production. Our in-house developments meet these requirements and save resources at the same time.

„If you want to consume safely,

you have to produce cleanly.“

Hohe Tanne

OUR CLEANING TECHNOLOGIES

SPK

the slightly different spray ball

- pressure range: 1–16 bar

- spray pattern: 180°up, 180° down or 360°

- no moving parts, insensitive to clogging by product residues

- 1.4404 (AISI 316L) - others on request

- ATEX exempt, as there are no moving parts

SWR

hydrodynamic surge cleaner

- pressure range: 1–9 bar

- spray pattern: 360° / 270° / 180° - up or down

- without wear-prone ball bearings

- 3 models: -018 / -032 / -060

- 1.4404 (AISI 316L) - others on request

- FDA compliant

SWR-004

hydrodynamic surge cleaner

- pressure range: 1–5 bar

- spray pattern: 360° und 180°

- without wear-prone ball bearings

- lower-cost

- FDA compliant

ORB

fluid-driven orbital cleaner for stubborn soiling

- pressure range: 2–16 bar

- 360° orbital spray pattern

- no electronic supply necessary

- various turbine designs and gear ratios for valid processes

- with protective cage on request

- 1.4404 (AISI 316L) - others on request

- FDA compliant or ATEX Zone 1

NEW: HJC

motor-driven high-pressure orbital cleaner

- pressure range: up to 250 bar

- 360° orbital spray pattern

- easy integration into existing systems

- high cleaning performance with reduced water consumption

- immersion depth stepless adjustable

- IP68 protection class

- 1.4404 (AISI 316L) - others on request

- FDA compliant

AJC

programmable jet cleaner for resource-saving and needs-based cleaning

- pressure range: 1–160 bar

- spray pattern: 360° tank cleaning with any design of the cleaning paths

- encapsulated media flow - no gear parts through which the medium flows

- 2 models: single or double nozzle

- 1.4404 (AISI 316L) - others on request

- FDA compliant

AJC-Mini

programmable jet cleaner for resource-saving and needs-based cleaning

- pressure range: 1–16 bar (up to 160 bar on request)

- spray pattern: 360° tank cleaning with any design of the cleaning paths

- encapsulated media flow - no gear parts through which the medium flows

- 2 models: single or double nozzle

- 1.4404 (AISI 316L) - others on request

- FDA compliant

- WEIGHT ONLY 3.5 KG

click here for the product video

RNO

ring nozzle

- pressure range: 1–16 bar

- inline cleaning of valves

- easy installation

- available in almost all common flange sizes, special shapes on request

- 1.4404 (AISI 316L) - others on request

- FDA compliant

HUB

lifting units according to customer requirements

- moving unit for cleaning devices - no permanent dwelling in the product area

- with integrated hygiene sluice

- easy installation - direct connection via flange or ceiling-floor mounting

- dimensions and connections on customer request

- Hygienic Design

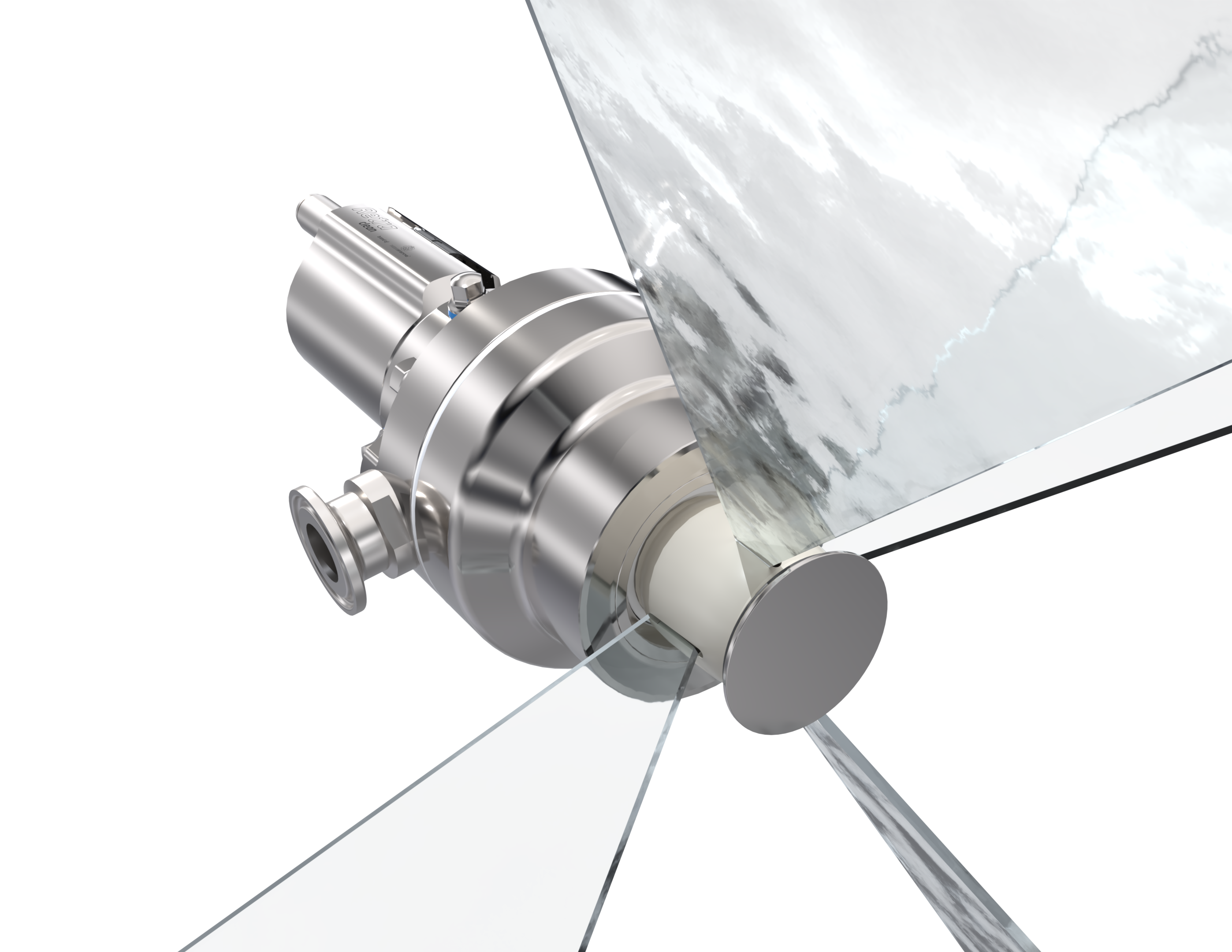

RET

retractor for automated tank cleaning

- pressure range: up to 16 bar

- fully automatic extension and retraction of the cleaning head

- main connection according to customer requirements: welded or screw connection

- with rotary cleaners or static spray pattern

- steam sterilizable

- 1.4404 (AISI 316L) - others on request

- FDA complaint, USP Class VI on request

MAS

the right tool for our products

- simple assembly and disassembly

- no scratching or damage to surfaces

- avoiding hygiene risks

- available in all common wrench sizes for our products

- Aluminum - anodized

Interested?

Our sales representatives will be happy to help you: